VRF Systems

LG’s Multi-V 5 Heat Recovery systems allow for fan coils to operate in heating mode or cooling mode, independent of the other fan coils on the system. This functionality is akin to a 4-pipe chiller/boiler system, which allows for independent mode operation between different fan coils at the same time.

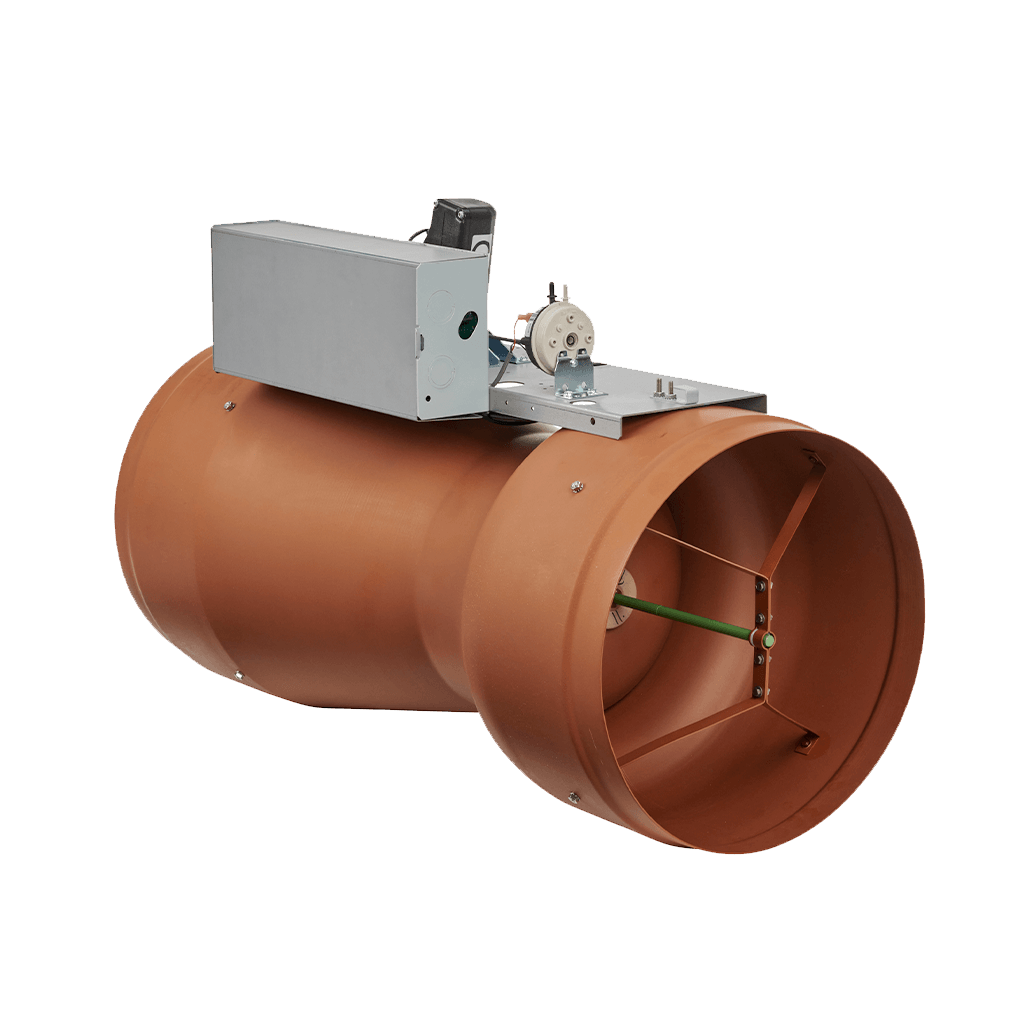

Unlike traditional water-based systems, which would use 4 large diameter water pipes to transfer heat, LG VRF Heat Recovery systems do this with only (3) smaller refrigerant pipes. Motorized valves within the heat recovery boxes open or close to let the desired refrigerant phase (Hot Gas, Liquid or Low pressure vapor) to the appropriate fan coil. Multi-V Heat Recovery is available in both air-cooled and water-cooled models. LG Multi-V is also one of the very few manufacturers that offer Heat Recovery on smaller single-phase air-cooled systems.

Born out of densely populated markets in Asia, VRF systems are some of the quietest HVAC technologies available anywhere. The heart of any DX (Direct Expansion) cooling system is the compressor, which is typically the largest contributor to noise pollution in HVAC systems. Unlike conventional systems in the U.S., LG VRF systems utilize inverter compressors that vary their speed. The majority of the time, HVAC systems do not require their full load so these compressors do not run at full speed very often. Even at full speed, inverter compressors do not emit a significant amount of noise during operation.

LG Inverter scroll compressors generate very high pressures with only a fraction of the sound levels of a conventional compressor. The outdoor unit condenser fans are also variable speed to match the load requirements to limit noise and energy usage. The newly designed Multi-V 5 air-cooled condenser fans have been designed to replicate the tubercles found on whale fins to generate more airflow with less noise and energy consumption. This is just one small example of LG’s focus on reducing both sound generation and energy consumption.

VRF systems operate at around 25% less airflow per ton of cooling than conventional systems, which results in lower air velocity levels indoors. Lower sound levels indoors and outdoors create a more comfortable environment for end users and neighbors alike.

LG Electronics is one of the most recognized brands in the world for consumer products. Whether it’s the sleek mirror finish wall mounted fan coils or the very modern unit controllers in various colors, LG always positions the consumer interface and aesthetics of their products at the foreground of their product offering.

LG Electronics maximizes each component in their equipment to transfer every bit of heat possible at the lowest energy cost. One advantage of building such optimized systems is that they can build units with smaller frames and footprints than many other competitors. Customers in New York City value each and every cubic inch of space and they often look to LG Multi-V as a solution to the toughest space constraints and challenging installations. Compared to conventional HVAC systems, LG VRF condensing units and ducted evaporators are much smaller in both size and weight.

VRF systems are split type systems that use copper piping to join outdoor condensing units with indoor evaporators to provide both cooling and heating to a space. The piping branches off to feed various units by way of LG factory supplied fittings and devices. The piping and devices are sized and selected by Klima New York.

There are no calculations for refrigerant pipe sizing by the contractor or engineer on VRF systems. Additionally, VRF systems run on their own control protocols and the only communication wiring needed for a given system is an 18 AWG pair of low cap, shielded, stranded wire between the outdoor unit and indoor units in a daisy chain pattern.

This is significantly easier than traditional systems with multiple indoor zones which would require field installed control devices and front end temperature control systems. Typical chilled water systems, for example would require field controllers, valves, actuators, temperature sensors and more. VRF systems do not require all of these field installed control devices and wiring so the controls installation time and cost are typically a fraction of what a conventional system would cost.